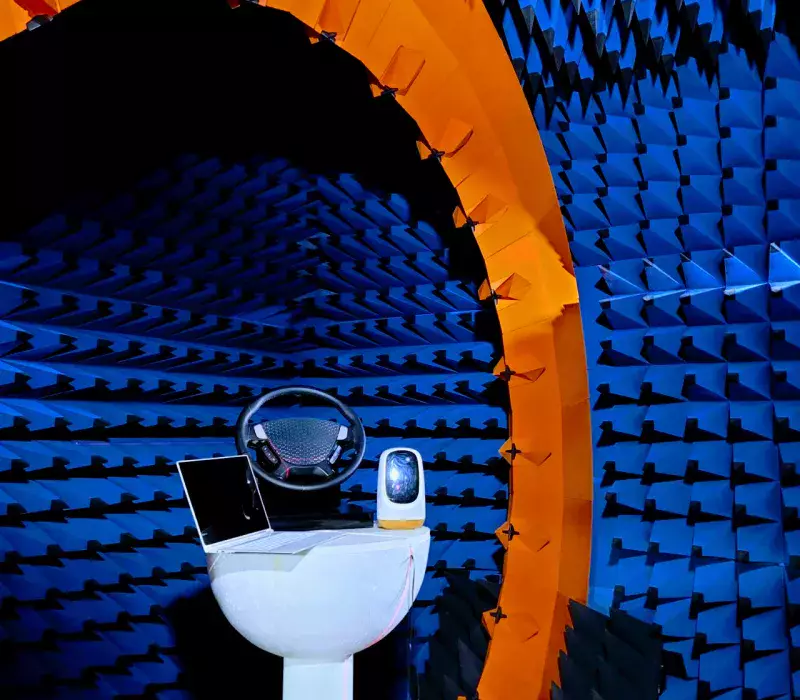

The SG24 has helped us tremendously, especially on antenna designs, active measurements, and telecom carrier certifications. The multi-probe technology also allows us to expedite the design process.

THE CHALLENGE

Pegatron, headquartered in Taiwan, is one of the world’s largest designers and manufacturers of consumer electronics for branded vendors. The company’s broad portfolio of products includes smartphones, laptops, tablets, IoT, smart home devices, and vehicle telematics and sensors.

An ongoing challenge for Pegatron is to ensure product design lifecycles are as short as possible. This not only lowers operational costs, but also allows the company to meet the time-to-market demands of its brand-name customers. Pegatron must also strictly adhere to evolving standards and certification requirements for next generation wireless devices. Getting fast and accurate measurements of antenna performance in each new device is therefore vital. De-risking wireless product design and shortening time-to-revenue becomes more difficult, however, with the arrival of Wi-Fi 6E and 5G New Radio. “There are more test items associated with the new 6E protocol than Wi-Fi 6 and LTE,” says William Wu, RF & Antenna Division Senior Director at Pegatron. Another challenge for Dr. Wu and his team is to have fast and accurate antenna-testing capabilities in frequencies above 6 GHz, covering the entire FR1 spectrum and extending into FR2 frequencies and beyond. Not only to support Wi-Fi 6E, but also to help Pegatron’s push into automotive electronics. In November 2021, Pegatron’s board of directors approved a $164m investment in new manufacturing equipment and facilities in North America to handle growing demand from electric-vehicle manufacturers.

Learn how Pegatron increased its test and measurement capacity to support expanding protocols and 5G standards.